Product

CROSSOVER SUBS

A Crossover sub is used to crossover from one connection size to another or as the disposable.

Component used to extend the connection life of a more expensive drill stem member. Crossover subs are available with:

➢ Box X Pin

➢ Box X Box

➢ Pin X Pin connections.

Crossover Subs are manufactured from AISI 4145M or 4140HT alloy steel. The connections are protected by a phosphate surface coating that minimum galling in initial make-up.

When ordering, please specify:

➢ Identify sub use. Example: Kelly subs, Crossover drill pipe to drill collar, drill collar to drill collar, bit sub, etc.

➢ Overall Length

➢ Largest Diameter

➢ Bore ID

➢ Size and type of upper and lower connection, indicating Pin or Box.

➢ For Reduced Section Subs, add: Diameter of reduced Section.

➢ Length of reduced section: As per API std. 8”, 36”, 48” or customer requirement.

FLOAT SUBS

Float subs are critical items in the drill string. We specialize in the manufacture and testing of these tools.

Float subs manufactured to suit your requirements including float subs with double shoulder proprietary connection available.

Float subs can be pressure testing our in-house testing facilities.

All types of connection and sizes available as per API, please contact us for additional information.

BIT SUBS

Bit Subs are used to connect the drill bit to the first piece of BHA equipment or to crossover connection in the drill string.

Drill bits are manufactured with a pin making make-up impossible without a bit sub.

BSI offers a complete line of bit subs.

Size availability ranges from 3-1/8” to 12” OD and 36” to 48” in length.

KELLY SAVER SUBS

The Kelly Saver Sub is used to extend the life of the Kelly by taking the connection wear each time it is made up to a drill stem component. The Saver sub connection is sacrificed because it can be easily repaired or inexpensively replaced.

Kelly Saver subs are manufactured from AISI 4145M or 4140HT material grade.

When ordering, please specify:

➢ Overall length : 36” , 42” or 48”

➢ Largest diameter

➢ Bore ID

➢ Size and type of upper and lower connection, Indicating pin or box.

LIFTING SUBS

BSI lift substitute are manufactured from Alloy steel AISI 4145H or 4140HT modified, in accordance to the requirement of API spec 7-1. Lift subs enable the efficient and safe handling of BHA equipment, and can be supplied with an 18°tapered shoulder or alternatively with a square shoulder.

When enquiring, please specify:

➢ Drill collar OD

➢ Tool joint OD

➢ Drill pipe OD

➢ Bore ID

➢ Drill collar connection size and type

➢ Bore ID

➢ Tapered or square shoulder.

HAMMER UNION

BSI offers a comprehensive range of standard Hammer Unions. Each union is thoroughly inspected to ensure long, dependable service in the most extreme conditions. The company maintains a large inventory and our manufacturing capability makes it possible to respond to short term delivery situations.

➢ Three lug nuts and self-locking ACME thread provide quick make-up and break-out.

➢ Color coded for quick identification.

➢ Manufactured from quality steel meeting ASTM and / or AISI standards.

➢ Range from 2” to 6” with cold working pressure from 500 to 20000 PSI.

PUP JOINT

Pup joint are short drill pipe used to adjust the length of the drill string and are available in standard lengths of 5’, 10’, 15’, 20’ and can be ordered to match other drill pipe dimensions. Pup joint are manufacture from AISI 4145H or 4140H-modified alloy.

BSI product offers a wide range drill string product and accessories with standard API or proprietary high performance connections to meet the most demanding drilling requirement.

-Repair & Re-Threading

-Testing

We repair and re-thread so that your tool can be used again, and again. All thread connections cut by BSI are gauged to ensure optimal fit and conformance to all requirement and specification.

Our daily production is capable of running two shifts as we understand the time sensitivity and urgency of all our customers – “Time is of the essence”. In this regard our customers can be assured of timely deliveries and competitive pricing. These are the strategic solutions that BSI can offer to our valued customers.

We have the expertise in Re-Threading :

.Drill Pipes, Drill Collar & Non-Magnetic.

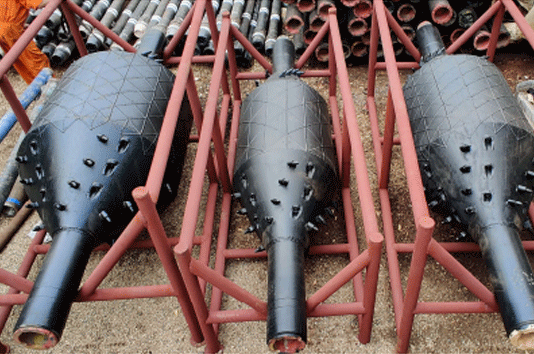

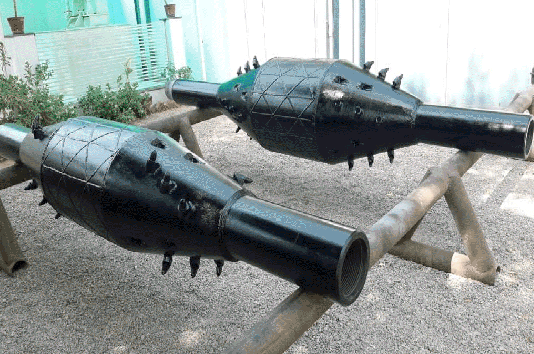

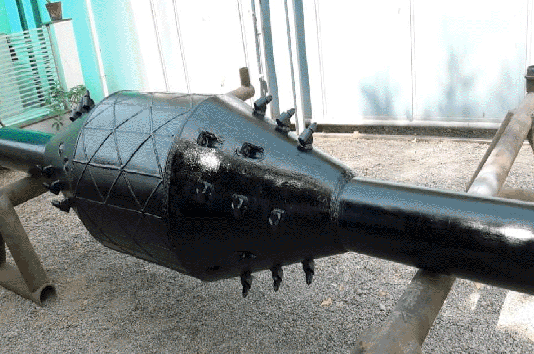

Steel Stabilizers & Non-Magnetic.

Steel Drill Stem Components.

Your Special Product.

We provide you exceptional value by offering a wide array of goods to meet your operational demands.

Steel Drill Stem Components , down hole components ( Packers, Sliding sleeve, Jar)

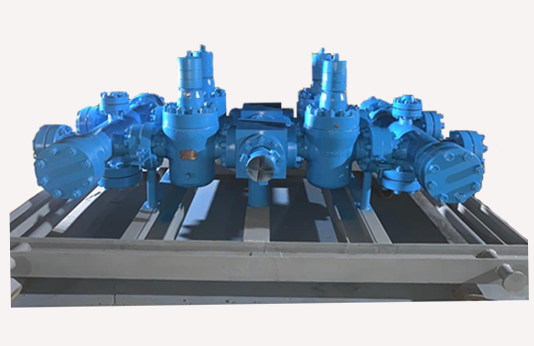

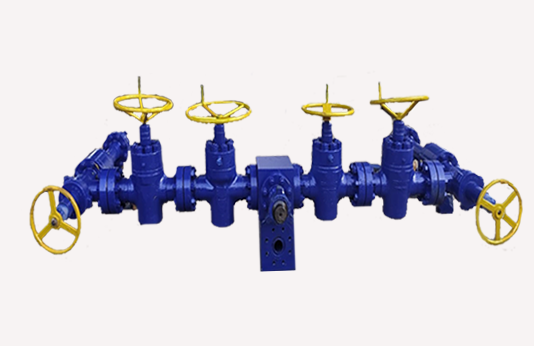

Testing / re-certification , slick line BOP , Well test choke manifold , SSV , Rig choke manifold .

Pressure Testing is carried out in a purpose built Test Bay at our facility in BSI. Which facilitates both Vertical and Horizontal Pressure Testing of Drilling Tools and Down-hole Equipment’s.

Pressure Testing can be carried out to our Specification/Procedures or to customer requirements.

Capable of Pressure Testing up to 20000 psi hydrostatic.

.png)

.png)

.png)

.png)

.png)